Cape Reed Tiles

CAPE REED TILES

STANDARD, HEAVY, LARGE, COMBINATION, TROPICAL AND GRATED

WE HAVE MANUFACTURED AND EXPORTED MORE THAN 3 MILLION CAPE REED TILES IN THE LAST TWO DECADES !

When it comes to installing a quality thatched roof, one of the most durable and aesthetically pleasing solutions for resorts and amusement parks are Cape Reed thatch tiles.

AFRICAN CAPE REED THATCH TILES: A MUST SEE 2 MINUTE VIDEO >>

These tiles can be used covering a large variety of structures: Thatch umbrellas, gazebos, Palapas, Tiki Huts, animal cages in zoos, etc. etc. (For resorts, hotels and houses our 20 year warranty Fiber Thatch Synthetic Tiles is the solution).

Over the years, we’ve continuously sought to improve our design and manufacturing approach to further strengthen these reeds beyond what nature was able to accomplish and to also amplify Cape reed’s aesthetic versatility. Our African Cape reed thatch tile products were specifically designed to maximize durability while giving you creativity free reign over your project.

HERE’S A QUICK LOOK AT WHAT WE MEAN:

-

Standard

Our Standard Cape reed thatch tiles provides a rugged, sturdy, stepped roof appearance and can cover almost any shape of roof. There insulating properties are amazing and the tiles provide a 90% water tight roof. The stepped straight line finish provides that precise clean look so sought after by Europeans.

-

Heavy

The Heavy Cape reed thatch tiles , similar to appearance to the standard Cape reed tiles, are packed more densely with thinner reed stalks that allow more reeds fitted into the binding strip. This makes the tile a perfect choice to top off a circular structure because the high reed density allows for a “fanning out” without gaps when the tile is used on the top rod of an umbrella.

-

Large

The Large Cape reed thatch tiles are tiles with the reed particles measuring 20 cm (24”) longer. The tile is very popular on beach umbrellas where only 3 tiles and a top cone on a very light frame provide a 2m (6’6”) shade covering. The tiles are also often used in the place of the standard Cape reed tiles to enlarge the diameter of an umbrella or to provide a larger overhang.

-

Combination

Our Combination Cape reed thatch tiles are one of our proudest inventions. This tile is the ultimate tile. Because of its uniqueness we have successfully patented this tile S.A.Patent No. 2006/03805 refers). The tile consists of a layer of the 20 year warranty Fiber synthetic material covering and protecting the natural material underneath. The result is a tile where the accelerated degradation is halted while the insulating properties of the Cape Reed are retained.

-

Tropical

The Tropical Cape reed thatch tiles are tiles used where a natural, rustic tropical finish is required. We glue the reed particles into the glue so that the flower side are shown. The effect is that tropical look. No other tile weather so beautiful. Roofs with tropical tiles way past the replacement dates still look as if it was thatched only a year ago. The tile easily gives double the life expectancy of any standard Cape reed tile.

-

Grated

Our Grated Cape reed thatch tiles. The tiles were designed so that the appearance will match the traditional custom thatch smooth appearance. We are the only company that had perfected the layered finish in a thatch tile.

-

Corner tiles

Our Cape reed corner tiles. The Cape reed corner thatch tile is used to cover the end of a 90-degree corner of a square or rectangular thatch roof. (click here for more information)

-

Top cones

Our Cape reed top cones. The top cone forms a cap on the top of a circular, square, hexagonal or octagonal roof.(click here for more information)

contact us today

Contact us today for a free quote, or to BECOME A DISTRIBUTOR

CAPE REED TILES Products

STANDARD CAPE REED TILES

-

Product Information

Size: 800mm(32”) x 450mm(18”) x 25mm(1”)

Weight: +/-4.4kg

Product Code: T4

Description: The tiles are manufactured from Cape Thatch Reed (Thamnochortus Insignis). Used to cover straight and round structures.

-

Container Information

Box size: 460mm x 810mm x 210mm

Qty Per Box: 6

Volume Per Box: 0.077 m3

20ft Container (33 m3) : 418 boxes

40ft Container (67 m3) : 838 boxes

HC 40ft Container (76 m3) : 978 boxes

Fiber Reed - Top Cone

ButtonHEAVY CAPE REED TILES

-

Product Information

Size: 800mm(32”) x 450mm(18”) x 25mm(1”)

Weight: +/-4.4kg

Product Code: T5

Description: The heavy thatch tile is a denser tile that contains more Cape reed than standard African tiles. The “fanning out” ability of the tile is better and therefore used at the top of a circular structure. The heavy tile is used to cover the top 2 rows of a circular structure – just below the top cone.

-

Container Information

Box size: 830mm x 470mm x 80mm

Qty Per Box: 2

Volume Per Box: 0.0312 m3

20ft Container (33 m3) : 1057 boxes

40ft Container (67 m3) : 2147 boxes

HC 40ft Container (76 m3) : 2435 boxes

LARGE CAPE REED TILES

-

Product Information

Size: 800mm(32”) x 750mm(18”) x 25mm(1”)

Weight: +/-4.4kg

Product Code: T13

Description: The tiles are manufactured from Cape Thatch Reed (Thamnochortus Insignis). Used to cover the 2.0m round umbrellas.

EXCLUSIVE TO FIBER ROOFING CC

-

Container Information

Box size: 840mm x 940mm x 110mm

Qty Per Box: 3

Volume Per Box: 0.0868 m3

20ft Container (33 m3) : 380 boxes

40ft Container (67 m3) : 771 boxes

HC 40ft Container (76 m3) : 875 boxes

Fiber Reed - Top Cone

ButtonCOMBINATION CAPE REED TILES

-

Product Information

Size: 800mm(32”) x 450mm(18”) x 25mm(1”)

Weight: +/-4.4kg

Product Code: T9

Description: A Combination Fiber/Reed tile has a layer of Polyolefin fitted on top of the Reed to protect the reed underneath. Tile sizes are the same than normal reed tiles. Top Cone sizes also

the same.

EXCLUSIVE TO FIBER ROOFING cc

SOUTH AFRICAN PATENTED NO: 2006/03805

-

Container Information

Box size: 460mm x 810mm x 210mm

Qty Per Box: 6

Volume Per Box: 0.077 m3

20ft Container (33 m3) : 418 boxes

40ft Container (67 m3) : 838 boxes

HC 40ft Container (76 m3) : 978 boxes

TROPICAL CAPE REED TILES

-

Product Information

Size: 800mm(32”) x 700mm(28”) x 25mm(1”)

Weight: +/-4.4kg

Product Code: T7

Description: The tiles are manufactured from Cape Thatch Reed (Thamnochortus Insignis). Tropical tiles are made using the flower or seed part of the reed. A tropical finish is obtained.

-

Container Information

Box size: 840mm x 940mm x 110mm

Qty Per Box: 4

Volume Per Box: 0.0312m3

20ft Container (33 m3) : 1057 boxes

40ft Container (67 m3) : 2147 boxes

HC 40ft Container (76 m3) : 2435 boxes

Fiber Reed - Top Cone

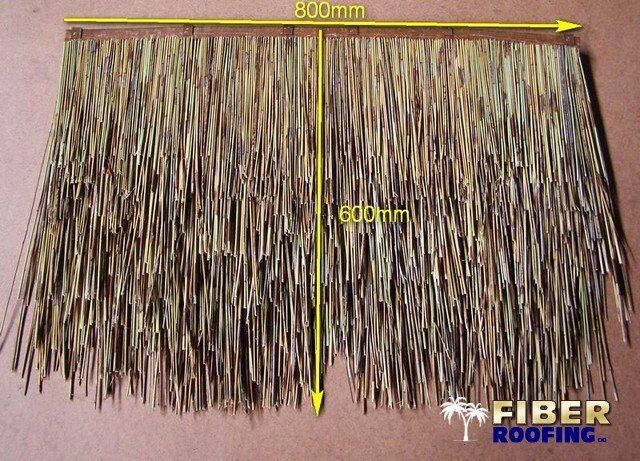

ButtonGRATED CAPE REED TILES

-

Product Information

Size: 800mm(32”) x 600mm(24”) x 25mm(1”)

Weight: +/-4.4kg

Product Code: T6

Description: The tiles are manufactured from Cape Thatch Reed (Thamnochortus Insignis). Grated Cape reed thatch tiles are created with varying reed lengths for a multiple layer effect.

EXCLUSIVE TO FIBER ROOFING CC

-

Container Information

Box size: 840mm x 940mm x 110mm

Qty Per Box: 6

Volume Per Box: 0.0312 m3

20ft Container (33 m3) : 1057 boxes

40ft Container (67 m3) : 2147 boxes

HC 40ft Container (76 m3) : 2435 boxes

contact us today

Contact us today for a free quote, or to BECOME A DISTRIBUTOR

WHY USE CAPE REED TO MANUFACTURE TILES?

We have manufactured thatch tiles from thatch grass (hyparhenia dissoluta) which grows in abundance on the plains of Southern Africa, from Makuti, Bali palm, Alang Alang and Thatch Reed from Europe, but none of these materials can live up to or match Cape reed as far as durability and longevity are concerned. (We still manufacture on demand tiles using some of the other materials.)

Cape reed (Thamnochortus Insignis) grows in an arid soil environment in the Cape Province in a small area near the town of Albertinia. Plants are harvested between 5 and 7 years. Harvesting promotes growth. Compared to all the other natural materials the stems have a solid core. It is not possible to squash the stems between your fingers and stems do not snap easily.

Furthermore, the cell and fibre structures within the plant do not deteriorate when it is dried, as is the case with all the other inferior natural materials. Cape reed has been used as thatching materials for hundreds of years. There are many fine examples of Colonial Cape Reed houses dating from a previous century in South Africa and the material have been used in resorts all over the globe. Using Cape Reed to manufacture the bulk of our tiles was motivated by these unique assets.

BENEFITS OF THE CAPE REED THATCH TILES

For nearly four decades we have studied and worked with Cape Reed. We have built up lifelong supplier relationships and friendships with the farmers growing and supplying the cape reed. The design of the tiles, the installation methodologies, the drying and pre-treatment of the plant matter, and the fastening mechanisms to hold the reeds together – all play a role in the long term success of a roof installation. Here’s what makes our Cape reed thatch tiles such a superior choice for thatched roof projects.

-

Cape Reed is Durable:

The reeds are thick and solid on the inside. Unlike species of reeds with hollow centres, the solid centre of Cape reed thatch makes the reed significantly harder to break. The reed does not absorb moisture so easily and on a roof it sheds rainwater much faster. The result is that tiles have an average lifespan of 5-7 years, and sometimes even longer. This kind of durability is not available with any of the other thatching materials, often cheaper, but will need to be replaced in 3-4 years.

-

Cape reed takes between 5 to 7 years to fully mature:

which also boosts the strength of the reed stem and its ability to resist winds. Most plant species used for thatch are often harvested after just one year, which makes them flimsy and easy to break. All of the Cape reed thatch tiles manufactured by Fiber Roofing use only fully matured reeds, which have the most structural integrity.

-

Water proofing:

Because of the natural ability of Cape reed to shed water, Cape reed tiles are more than 90% water proof. Other materials often, when used in tile format, leave big gaps resulting in a roof not at all waterproof. We can also fit a layer of plastic in between the tiles that will provide a 100% water proof.

-

Covers any roof shape:

Our Cape reed thatch tiles are designed to cover any roof shape. The tiles are small enough that they can be layered effectively to conform to any shape, but large enough to keep installation times short. This is different from thatch rolls, which are more troublesome to install and are harder to contour to the shape of the structure. Our Cape reed thatch tiles can easily be cut to size, and can be quickly layered to create a variety of effects used on gazebos, umbrellas or any possible roof structure.

CAPE REED THATCH TILE INSTALLATION

Our Cape reed tiles were designed with quick and simple installation in mind. Whether you’re installing the tiles on a metal gazebo, a wooden structure or a thatched umbrella, no expertize are needed.

-

Roof Pitch:

When installing Cape reed thatch tiles it is important to only attach to structures with a roof pitch of 30 degrees or more. A thatched roof needs a greater pitch than a regular construction because the pitch plays a role in the effectiveness of water drainage. A higher pitch puts the roof at a less direct angle to the sun (which creates shade),and is more resistant to the effects of winds and rain.

-

Steel Frame Installation:

Clip the Cape reed thatch tiles onto a 8mm diameter galvanized or powder coated steel rod, using the 6 clips affixed to the binding strip. Note that the colour of the clips and the binding strip matches. This is to ensure full blending of the tiles from any visual angle. Small details such as matching clips and rubber, fitting 6 clips instead of 5, distinguish Fiber Roofing from all the other manufacturers in South Africa. The tiles should be installed in layered courses with a spacing of 350 mm and an overlap of 100 mm.

-

Wooden Frame (batten) installation method:

You can also use nails or staples to attach the tile through the rubber binding strip directly to timber battens. With this type of Cape reed tile installation, ensure that any nails or screws are driven all the way into the binding strip and are not visible. Ensure that you create a 100 mm overlap on these as well to increase resistance to environmental factors and create a fuller appearance.

-

Tile Coverage:

A square meter of roof area will require approximately 3.5 standard Cape reed tiles for effective coverage. The number may vary based on the effect you are seeking as you may need to create layers or a fanning effect.

Contact us today

for a free quote, or to BECOME A DISTRIBUTOR

contact us

Complete the form below and we'll get back to you as soon as we can.

We will get back to you as soon as possible.

Please try again later.

We’ve installed thousands of roofs over the years and can provide you with any information you need, whether it’s for the Cape reed thatch tiles or one of our many other excellent products. We’ve seen every scenario out there and can solve any installation issue. We can even send a team to your project site and directly help you finish the work with stellar results.

DON’T FORGET…OUR CUSTOMERS ARE LIKE FAMILY TO US…IF YOU NEED OUR HELP WITH ANYTHING, WHETHER IT’S CAPE REED THATCH TILE INSTALLATION, OR ANYTHING ELSE, JUST LET US KNOW. YOU CAN GIVE US A CALL AT (+27) 11 903 9204, OR DROP US A LINE

HERE.

Products

VISIT

Plot 22, R59 Industrial Park,

Old Alberton Vereeniging Rd/

Springbok Rd 1871 Midvaal, South Africa

CONTACT

Phone: (+27) 11 903 9204

Email:

info@fiberroofing.com

All Rights Reserved | Fiber Roofing | Privacy Policy